Broom Base Plastic Mould

Basic Info

| Model NO. | SY-MB007 |

| Shaping Mode | Injection Mould |

| Surface Finish Process | Heat Treatment |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Runner | Cold Runner |

| Design Software | PRO-E |

| Installation | Fixed |

| Standard | Hasco |

| Customized | Customized |

| Transport Package | Carton as Custom |

| Specification | plastic |

| Trademark | Suyuan-tech |

| Origin | Jiangsu, China |

| HS Code | 84807100 |

| Production Capacity | 50 PCS/Month |

Product Description

| Model | SY-MB007 |

| Usage | household |

| Core material | P20 |

| Cavity | 1X2 |

| Plastic material | PP |

| Mould size(mm) | 250*255*400 |

| Mould life(shots) | 500000 |

| Mould weight(kg) | 200 |

| Design software | Pro-E |

| Runner type | Hot runner |

| Sample time(days) | 25 |

3D Drawing Solution Plastic Injection Mould Maker

Suyuan Technology is a company which has more than 15 years experience on plastic injection. As a manufacturing import and export company who concentrate on design, development and making of high quality plastic moulds and plastic injection, with the increasement of business and customer reputation, we go deeper into the design, development, production and sales of innovative ODM&OEM products.

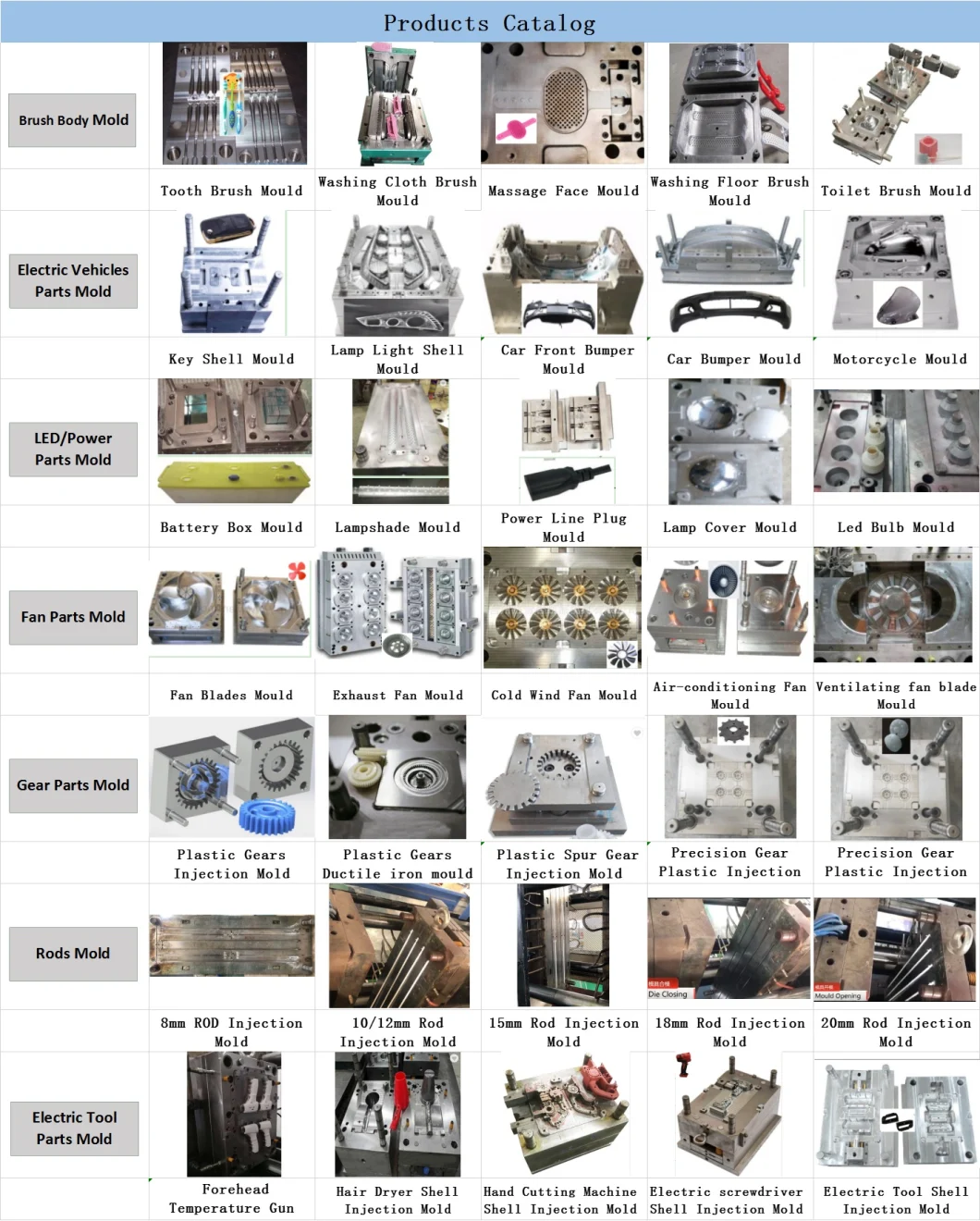

After years of development, our business line has been expanded to: Plastic brush body,Electric vehicle plastic shell,LED/Power shell,Plastic fan blade,Plastic gear,Plastic rods,Electric tool plastic shell.Providing of innovation products and solutions are our core business. Our products are mainly sold to the manufacturers or the traders

We have a solid team with rich experiences in industrial design, 3D structure design, tooling making, certificate consulting, project management, QA/QC, production management. We offer our customers not only reliable and competitive products, but also professional services and solutions that enables them realize their products ideas for catching business opportunities and value.

The picture shown is the customized product we made for our customer, for reference only. Any OEM service is welcomed. High quality ,fast delivery and fair price is highly strictly controlled here.

1) Description of the product| Name | Precision injection mould made in China |

| The company's strength | 1). Efficient team in exporting mould 2). Delivery on time 3). Excellent equipment 4). High quality and competitive price |

| Core & cavity material | Saarstahl, Assab, AISI & JIS, DAIDOSTEEL, ALCOA, S136, 1.2311, 1.2738, NAK80 2344, 420, 2083 etc |

| Plastic material | ABS, ABS+PC, PP, PS, POM PVC, TPE, TPU, Acetal, PA66 PA6, PA66+30%GF, PPS, etc |

| Main processing Equipment | CNC, wire cutting, Grinding machine, Lathe, Drill Press, EDM center |

| Practicable software | PRO/E, UG. Solidworks, AUTO CAD |

| Business Scope | 1). Plastic Mould Design 2). Mould making/Injection parts/Cleaning tool/Hand tool etc 3). Plastic parts injection 4). Reverse Engineering 5). Rapid prototype manufacturing |

| Primary Competitive Advantages | 1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome |

2) Our product

Precision injecion mould

3) Our Design & Development team

4) Our manufacturing process

5) Our quality control team

6) Packing,storage and delivery

FAQ:

Q: Are you a factory or trading company?

A:We are a direct factory.

Q: I have no 3D drawing,How should i get start this new project?

A: You can provide the sample,we will help to finish the drawing design.

Q: Why choose us?

A: High quality,factory price,timely delivery and professional service.

Q: How does your factory do regarding the quality control?

A: Quality is priority.We always attach great importance to quality controlling from every beginning to the very end.All the moulds,the QC measure with corresponding measuring equipments regularly.