Electronic Spare Parts Injection Molded Plastic Parts Injection Mold

Basic Info

| Model NO. | HX-1021 |

| Trademark | Haixin |

| Origin | China |

| HS Code | 39269090 |

| Production Capacity | 10000-20000PCS/Day |

Product Description

Company Introduction:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

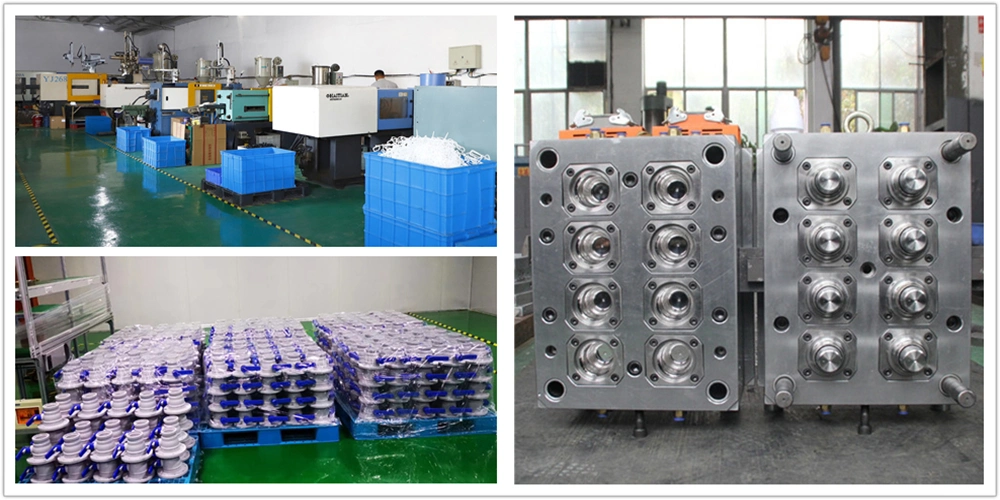

We focus on plastic injection molding production since the year 2000With 4,000 square meters dust-free workshop, and 15 sets of injection molding machinefrom 8ton to 200ton, all of them equipped with manipulator, Automatic and intelligent production is realizedThey will be operated by our experienced technician, adjust temperature, pressure,flow speed and mold, it is not easy, but we can handle these 15 warriors, so they can dothe best productionStable raw material supply chain, PP, PC, ABS, LDPE, HDPE, PVC, TPR, PU, and so on. After mixing and adjusting by experienced experts, become the most precise formula for your productIntelligent machine, precisely formula, and mould, experienced technician, make allthe imagination of the product come true

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

| Material | PP, PS, ABS |

| Color | Any color available |

| Package | Standard export carton |

| Sample Time | 5-7 working days |

| Logo | Provide Pantone color code, logo design, size |

| Design | AI, CAD, Core Draw,Original sample |

Product View:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Fillerwhich can improve the strength and heat resistance of plastics and reduce the cost. For example, the addition of wood powder to phenolic resin can greatly reduce the cost, make phenolic plastic one of the cheapest plastics, and significantly improve the mechanical strength. Fillers can be divided into organic fillers and inorganic fillers, the former such as wood powder, rags, paper and various fabric fibers, and the latter such as glass fiber, diatomite, asbestos, carbon black, etc.

Plasticizer

Plasticizers can increase the plasticity and softness of plastics, reduce brittleness, and make plastics easy to process and shape. Plasticizers are generally high boiling organic compounds that are miscible with resin, non-toxic, odorless and stable to light and heat. Phthalates are the most commonly used. For example, in the production of PVC plastics, if more plasticizers are added, soft PVC plastics can be obtained. If no or less plasticizers are added (dosage < 10%), rigid PVC plastics can be obtained.

Stabilizer

In order to prevent the synthetic resin from being decomposed and damaged by light and heat in the process of processing and use, and prolong the service life, a stabilizer should be added to the plastic. Commonly used are stearate, epoxy resin, etc.

Colorant

Colorants can make plastics have various bright and beautiful colors. Organic dyes and inorganic pigments are commonly used as colorants.