Free Sample Customized Injection Mold for Plastic Helmet

Basic Info

| Model NO. | HW-164 |

| Mould Cavity | Single Cavity |

| Plastic Material | PVC |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Any Question Please Feel Free to Contact Us. |

| Mould Runner | Cold/Hot Runner - Point Way, Side Way, Follow Way |

| Mould Process Machine | CNC, EDM, Grinding, Wire-EDM, Milling, etc |

| Mould Life | 300K-500K Shots, Depend on Mold Steel |

| Mould Surface Treatment | Mirror, High Polishing |

| Mould Steel | S50c/P20h/718/H13/S136/2316/2738etc |

| Mould Design Software | Ug, Proe, CAD, Caxa etc. |

| Transport Package | Box |

| Specification | Custom |

| Trademark | HOWE or Custom |

| Origin | China |

| HS Code | 3901100001 |

| Production Capacity | 10000PCS/Week |

Packaging & Delivery

Package size per unit product 40.00cm * 30.00cm * 20.00cm Gross weight per unit product 10.000kgProduct Description

| Plastic Injection Mould and Molding Injection Details: | |

| Plastic Material: | PP,PPA,PC,ABS,NYLON,CRYLIC,HDPE,POM...etc |

| Steel of Cavity and Core: | Depends on the products,we will show suggestions to customer to choose the suitable material |

| Commonly use materials as below: | |

| Japanese: NAK80,SKD61,SK53,SKD11,DC53,SKH51,HPM2,etc | |

| SCHMOLZ: P20HH,2738,2083H,2343,2344,etc | |

| DIN: 1.2738,1.2083,1.2343,1.2344,etc | |

| AISI: P20,H13,D2,D6,M2,etc | |

| ASSAB: 718HH,Nimax,8402,8407,XW-10,XW-5,EM2,etc | |

| Steel of Mold Base: | Depends on product,we will show suggestions to customer to choose the most suitable material. |

| Mold Standard Components: | HASCO,MISUMI,MEUSBURGER,DME,etc |

| Runner: | 1. Hot Runner: Yodoo from Korea; Synventive from Netherland or as you request. |

| 2. Cold Runner | |

| Mold Life: | Depends on QTY plan to use suitable steel or as you request |

| Commonly used: | |

| 1. 300,000-500,000 shots for one year under normal use procedure for pre-hardness steel material. | |

| 2. 500,000 shots for one year under normal use procedure for heat treatment steel material. |

Other Products

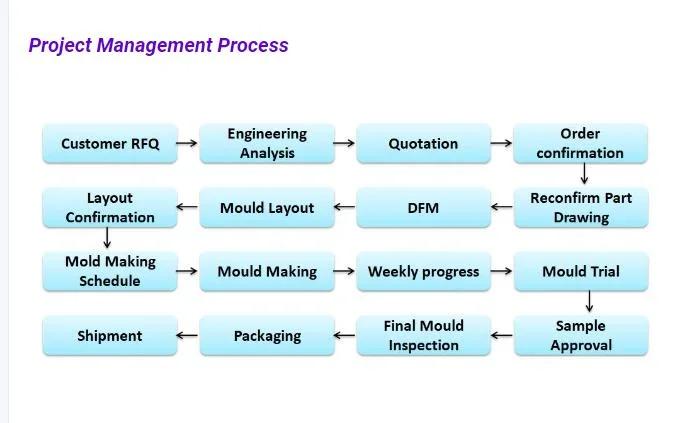

Howe Mould Quality Control1.Mould Material Q/Ca) mould steel checking (hardness,flaw detection)b) mould spare parts checking (hardness,size)2.Mould Making Process Q/Ca) design checking ( part design,mould design,mould engineering drawing)b) mould size checking (according to drawing)c) mould testing (check mould working,sample)

Our Advantages1. Competitive price 2. Continuance service and support 3. Diversified rich experienced skilled workers4. Custom R & D program coordination 5. Application expertise6. Quality reliability and long product life 7. Mature,perfect and excellence ,but simple designPackaging & Shipping

Company Profile

Howe was founded in 2010, as a fully certified ISO 9001:2015, we are proud to be a technologically advanced supplier that provides the increased manufacturing capabilities and efficiency our customers demand in injection mold and molding industry. We have currently employed over 40 staffs at the factory in Changan town, Dongguan City, China.As an experienced injection mold maker, HOWE meets all the requirements of manufacturing Automotive, Household appliance, Office appliance, Commodity, Telecommunication tools and Medical apparatus molds and products. We mainly export our molds and products to USA, Europe,India and Mexico.HOWE Mold starts with only the finest material - as measured by industry-leading standards for quality assurance and supplier evaluation - to ensure high-quality, precision-finished components. At HOWE Mold, we are dedicated to customer satisfaction and our team will continue to provide excellent parts, service and technical support to meet the needs of our customers and the demands of the industry. HOWE Mold customers have 24/7 access via a wide selection of communication channels. Toll-free telephone, fax, e-mail, skype, and web are all available. Since then we have expanded our reach into the international automotive market, we seek to work closely with our customers to provide the best service possible and ensure that project goals are met.

Customer visiting