Plastic Injection ABS Ppt PVC Mold/Mould/Molding/Moulding/Molds/Moulds for Car Household Appliances Furniture Commodity Electronic Home

Basic Info

| Model NO. | As the Customer demand |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Hardware |

| Runner | Hot or Cold Runner |

| Design Software | UG |

| Installation | Semi Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 24hours Based on Feedback |

| Plastic Parts Production Capacity | 100000 PCS/Month |

| Hardness of The Steel | 20~60 HRC |

| Drawing Format | Step., Igs., X_T, Dwg, Pdf, etc. |

| Main Services | 3D Design, Prototypes, Mold Design, Mold Making |

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.. |

| Plastic Injection Machine | 30ton-100ton |

| Mold Life | 200000 Shots |

| Machine Center | High-Speed CNC, Wire Cutting, EDM, Grinder, Great |

| Transport Package | Wooden Box |

| Specification | Customized Size |

| Trademark | YIZEMOULD |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 50000/Years |

Product Description

Plastic Injection ABS PPT PVC Mold/Mould/Molding/Moulding/Molds/Moulds for Car Household Appliances Furniture Commodity Electronic Home

Provide customization

In close cooperation with our customer engineers, we have designed and produced connectors and cable assemblies with extremely tight tolerances for many of the largest electronics companies and manufacturers in the world.

We offer all kinds of customization plastic injection mold and moldings

| Connector Series type | the precision plastic components connector, inserting plastic electrical connector and automotive aviation plug connector molding, board to board connector, wire to wire connector, etc. |

| Plastic injection medical series type | customized Medical customized thin-walled transparent multi-cavity mold and moulding products etc. |

| New energy plastic injection mold and molding parts | New Energy Automobile Fuse Box Plastic Mould etc. |

As we can see the showing photos of Case study products are as follow:

At the same time, we still provide customized precision mold and die parts for our customers. it means we can hold the quality and production.

Production advantage-130 employees, 180 precision processing equipmentProvide customers with a wide range of precision mold processing technical support, including turning, milling, plane, round, grinding, spark discharge, wire cutting discharge, PG optics, and other manufacturing processes.

Now let's get in touch to discuss how we can help with your project!

Why choose us?

1. We focus on producing high-precision plastic injection molding and parts as customers demand during 15+ years of experience. 2. The plastic injection mold and molding parts engineers group have offered professional services to help customer turn imagination into reality.3. We pay attention to reducing the customers' costs so that we provide the Fanuc injection texting molding machine and free injection molding assembly.4. At the same time, in Japan's Mitsubishi EA8A series and Japan's Sodick AG40LS series of high-end spark machines with automatic tool magazines, the accuracy tolerance can reach 0.003mm, and the clear angle can reach 0.01mm.

Our core plastic injection competitiveness

Our core competitiveness is to meet all kinds of small customized plastic parts that using lesser test time to ensure quality and delivery time while we having all kinds of injection machines to deal with different customer plastic part need.Product ApplicationInjection Mold Part: Plastic structural parts, Functional parts.Telecommunication fields: Connectors, Aviation plugs, 3C products, Aerospace Injection Molding. High-tech is also a branch of the business, such as Injection Moulding in the 5G era, New Energy Applications, Custom Medical Products, etc.Clients can expect: Product design and engineering assistance High production speeds and volumes High-quality parts and finishes Minimal post-processing Low labor costs Low scrap rates

Application

Comprehensive QC

| General Precision: 0.005mm | Dimensional Precision: ±0.001mm |

| Grinding precision within 0.001mm | Coordinate Precision: 0.001 |

| EDM/Wire Cut Precision within 0.005mm | Parallelism: ±0.002mm |

| EDM Angle clearance within R0.01 | Straightness: ±0.002mm |

| Straightness: ±0.002mm | Coaxiality: ±0.002mm |

| All Steel types available, special requests accommodated | Roundness: 0.0015mm |

| 7 Days Express Processing Service offered | Surface Roughness: Ra0.025 |

| MOQ 1 pcs Accepted | Surface Roughness (EDM) : Ra0.04 |

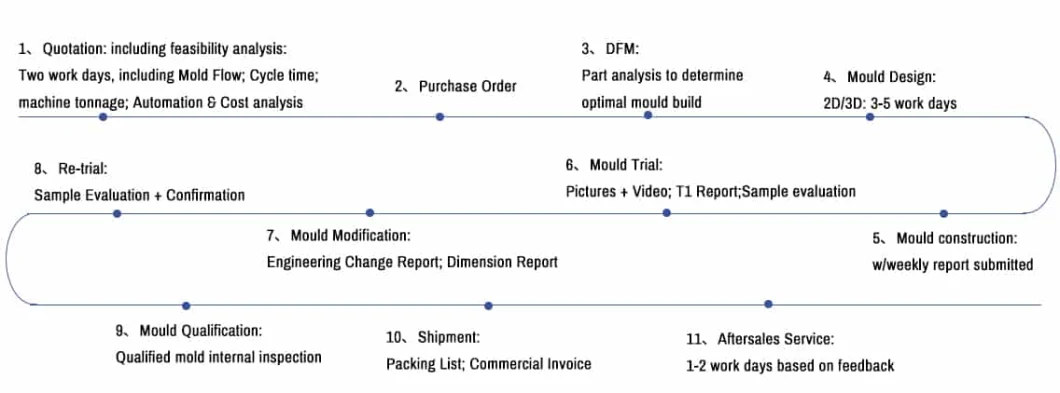

Duration Estimation

We have a simple step-by-step ordering process that can quickly analyze your needs. This allows us to provide you with the estimated duration of the order.

FAQ

* Are you a factory or trading company?

We are a plastic mold factory in Guangdong, China, welcome to visit us.

* Is YIZE an ISO-registered company?

Yes, YIZE is an ISO 9001:2015 certified mold manufacturer, we take pride in our constantly improving process and always try to add value for customers with the best efforts.

* What type of tooling services do you offer?

YIZE can help you manufacture, assemble, and printing for your plastic parts.

* Do you have an in-house mold design?

Yes, we have our own design team, our engineering manager has over 15 years of experience.

* How long it takes to design my mold?

The mold design timeline is dependent upon the complexity of the project. A simple construction mold can be designed in 1 or 2 days, while a complex mold can take several weeks. YIZEdesigners and the project manager will work closely with you to design your mold in a professional and efficient manner.