Plastic Disposable Forks/Spoon/Knife Injection Mold

Basic Info

| Model NO. | YP |

| Application | Household Appliances, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 2 Years Free Warranty |

| Transport Package | Wooden Case |

| Origin | China |

Product Description

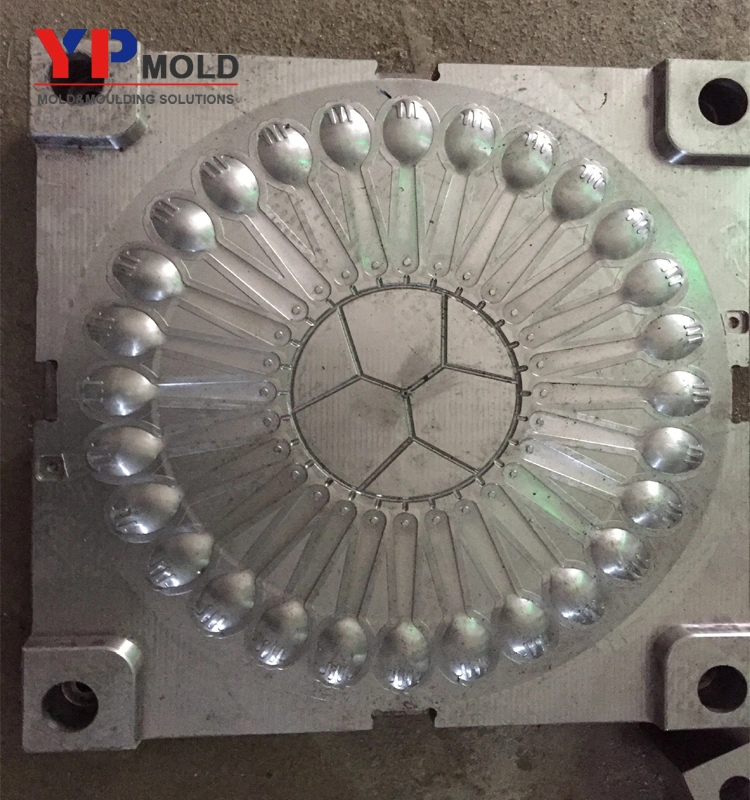

Plastic disposable forks/spoon/knife injection mold

Why choose yunpeng plastic mould?

Yunpeng injection Mold Factory focus on plastic injection mold more than 15 years.

1. Have experience for paper dispenser mould

2. Free 3 d Drawing service from plastic to plastic injection moulding tool design

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. Time is gold for you and for us, We have professional plastic injection mold tooling designer and plastic part producing line.

6. Plastic Injection Mould OEM & ODM Services

7. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory

8. Attachment is our latest finished plastic injection moulds.

Name | Plastic disposable forks/spoon/knife injection mold | |

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) | |

| Mould base | Standard mould base, LKM, HASCO etc. | |

| Cavity | Single/multi | |

| Runner | Hot/cold | |

| Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc | |

| Cooling system |

| |

| Design software | UG, PROE, CAD, CAXA etc. | |

| Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PC, PPE, PPO, etc. | |

| Surface treatment | Polish, texture, sand blasting, chrome plating | |

| Mould life | 300,000-1,000,000 shots | |

| Delivery time | 15-45days | |

| Pacakge |

| |

| Specification | As per customer's requirements |

Images for Plastic disposable forks/spoon/knife injection mold

Contact Tea for videos about Plastic disposable forks/spoon/knife injection mold

♦7*24 Hour Service

♦ Circumspect Technology Team

♦ All-around consultation centre

♦ Considerate training service

♦ Fast Service System

♦ Quick Global Delivery

Pre-sale Patient, serious, carefully Arrange to produce and care for the leadtime Before delivery , confirm the items carefully | After sales Arrange to delivery as soon as possible Confirm the items if arrived at customers' hands Get feedback from customers and try to do best |

FAQ About Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make stamping molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT , STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat_treatment /nitriding for the inejction mold plastic?

A5: Yes, As plastic mold fatory, we have long_term cooperated subsidiary factories that do those processes.They are professional and well reputed in our local market.

Q6: How long is the lead-time for a ?plastic injection mold?

A6: It all depends on the mold's size and complexity.Normally, the lead time is 25_45 days.If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by client.

Q8: How do you pack the china plastic moulds?

A8: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any

movement.

FAQ About Molded Products:

Q9: How many injection plastic mouldings machines do you have?

A9: We have 40 sets of plastic Injection Mouldings machines.

Q10: what is the minimum & maximum unit weight and size your machines can produce?

A10: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q11: What kind of plastic materials you usually use?

A11: We are specialized in producing plastic products with the following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

FAQ About Worldwide Delivery

Q12: Can you deliver the plastic moulds or plastic products to our factory?

A12: Yes, We have cooperated with many international logistics companies for years.

And we have full experience to manage the delivery directly to the client's factory or

appointed warehouse.

Hi dear, we sincerely invite you to visit our factory to see the whole production line, and please kindly send me email now so that we can send you the quotation list, have a good day !

BACK HOMEPAGE >>>