Plastic Oil Pure Water Bottle Blowing PP Bucket Dustbin Tray Barrel Drum Box Can Jar Cup Container Handle Cap Cover Lid Pet Preform Injection Inject Mold Mould

Basic Info

| Model NO. | KLBK03 |

| Application | Household Appliances, Furniture, Commodity, Home Use, Transportation |

| Runner | Hot Runner/Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Technical Guidance |

| Mould Name | Plastic Pail Bucket Mould |

| Processing | High Precision Tooling Machine |

| Delivery | 35 Days |

| Production | Injection Molding Machine |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | Kelong Mould |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 150sets/Years |

Product Description

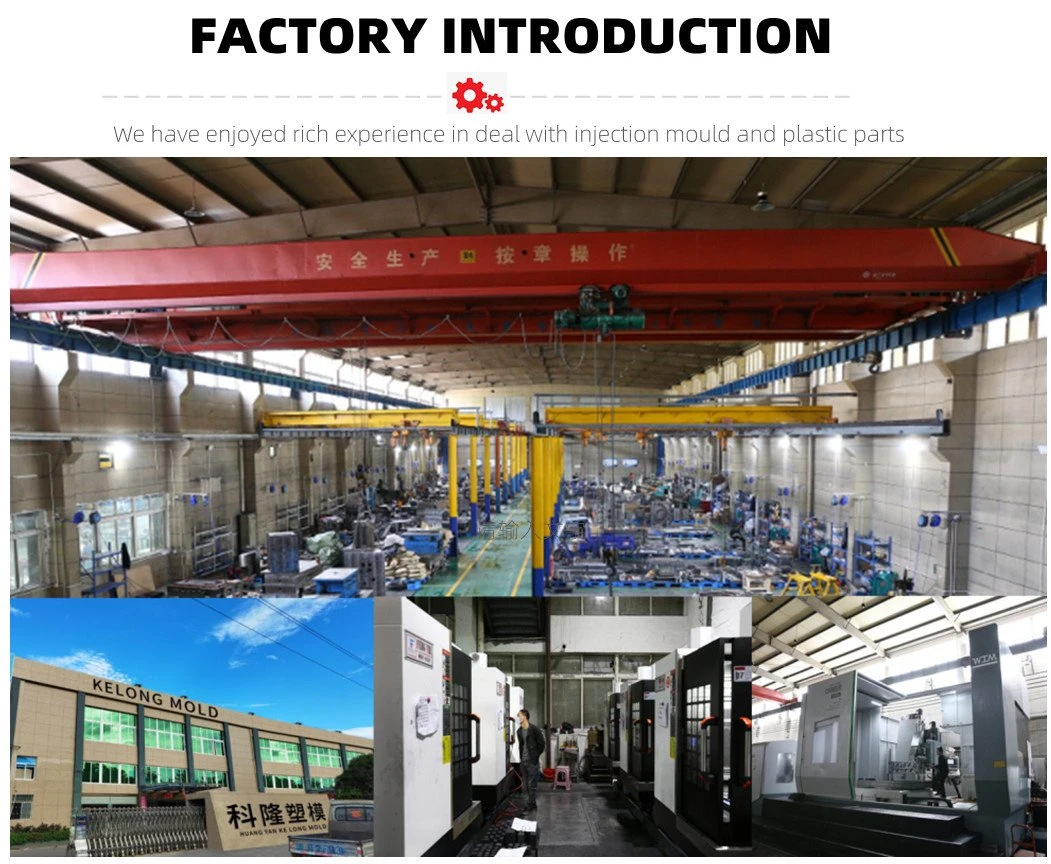

Kelong Mould supply different sizes of plastic bucket moulds from 1L to 35L,especially 5L,10L, 15L, 20L is the most popular sizes with different shapes like round type, square type, oval type and so on.During the bucket mould making, we use high precision tooling machines to control the bucket dimension well.With optimized mould structure,we could control the core shift within tolerance during molding. Kelong has support for multi-cavity mould solution for the bucket below 10L according to customer requirement. And for 1L bucket 4cavity mould is widely processed.Kelong Mould not only provide the mold,but also support for whole bucket production line solution which including the product design, mold design, mold tooling, mold making, mold production with injection molding machines also for the auxiliary machines. If you are interested in new bucket developing, welcome to contact us for more information.

Mould name: Plastic Bucket Mould Product size: 10L/20L Number of cavities: 1 cavity Die steel material: P20/718H//NAK80/S136H Mould size: 650*650*800mm Suitable for injection moulding machine: 650T Hot runner: YUDO/HASCO/Master Ejection system: Push plate ejection Mould cycle time: 35S Mould life: One million Mould lead time: 45-65 days Mould characteristics: 1. The mould structure is complex, the beryllium copper material is used, and the cooling effect is better. 2. The travel switch precisely controls the ejection process. 3. The oil-water integrated machine is more convenient to use and operate, and the copper guide sleeve is wear-resistant. |

1.

Q: Where is your company or factory?

A: We are located in Zhejiang, Taizhou, We have our own factory.

2.

Q: Can you make design?

A: We'll be glad to make designs for you, both product and mould, and for free.

Complete product 2D & 3D and mould 2D & 3D will supply to clients after order.

3.

Q: What type of mould you can make?

A: We can make all kinds of plastic injection mould, especially rich Experience

on household moulds.

4.

Q: What type of files can you accept?

A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.

5.

Q: What type of steel do you use?

A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#

6.

Q: What kind of material you use for test mould and production?

A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC,

We have rich experience for manufacturing product with these materials and know

how to adjust Parameter to get the perfect product.

7.

Q: How to send sample?

A: The quotation we offer you including The cost of sample delivery 2 times samples by

DHL, UPS, EMS,FEDEX or TNT.