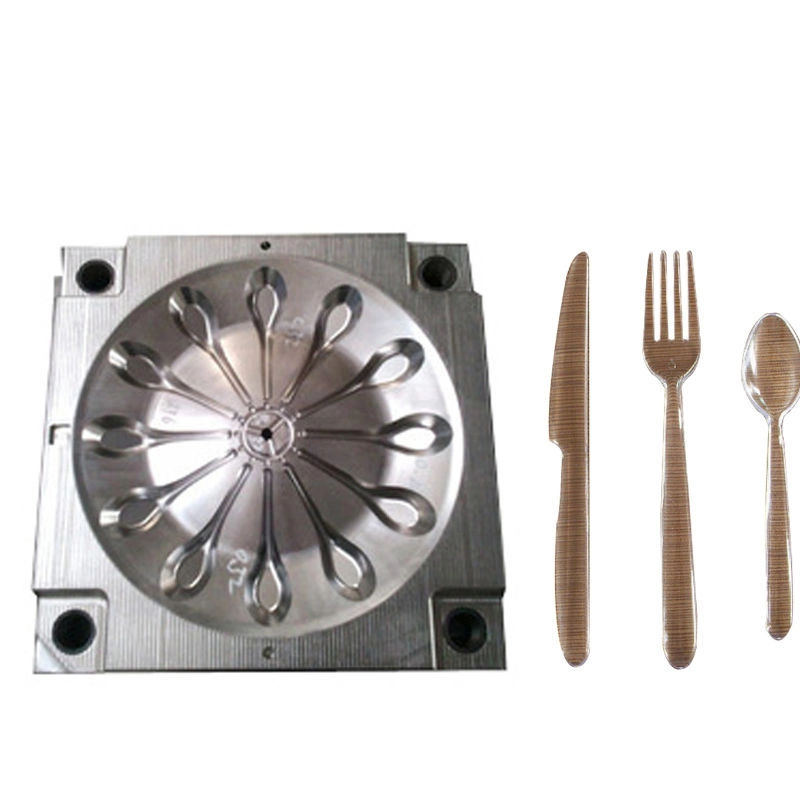

Customized Disposable Tableware Knives and Forks Plastic Injection Mold Mould

Basic Info

| Model NO. | HDIM220622-2 |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | Maintenance and Repair |

| Product Name | Plastic Injection Molding |

| Hardness of Steel | 33-38HRC Prehard, 46~56 HRC Hardened |

| Tolerance | +/ - 0.005 mm |

| Surface Treatment | Polish,Texture,Painting,Screen Printing,Coating,Tu |

| Cavity | Single/Family/Multi |

| Mold Hot Runner | Dme, Hasco, Yudo, Moldmaster, Hrs, Synventive, etc |

| Outside Package | Standard Wooden Casesor as Your Requirement |

| Molud Standard | Hasco,Dme,Meusburger,JIS,China Lkm Standard |

| Transport Package | Standard Wooden Casesor as Your Requirement |

| Specification | Depends on customer′s requirements. |

| Trademark | None |

| Origin | China |

| Production Capacity | 800 Sets Per Year |

Product Description

PRODUCT PARAMETERS

| Item Name | Customized Disposable Tableware Knives and Forks Plastic Injection Mold Mould |

Mould Core/Cavity | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,P20, P20HH, H13, 420ss etc. |

Hardness of steel | 33-38HRC prehard, 46~56 HRC hardened |

Mould Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

Mould Base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,1050,P20 ) |

Cavity | Single/family/Multi |

Runner | Hot/Cold Runner |

Mould Size | 150*150mm Min, 3000*2500mm Max |

Surface of Mould | EDM VDI/ High Polish&Texture |

Plastic material | PP, PC, PS, PE, PET, POM, PA, PU, PVC, ABS, HIPS, PMMA, Nylon, and with GF, etc. |

Mould Life | Prototype 1000-25,000; preproduction 50,000-10,0000; High production 300,000-1,000,000 shots based on Volume requirements |

Specification | Depends on the customer's requirements. |

Trade terms | FOB Shenzhen, EXW, CIF |

Export to | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

Mold hot runner | DME, HASCO, YUDO, Mold-Masters, HRS, Synventive, etc, or per customer requirement |

Mold gate type | point gate, side gate, sub gate, tunnel gate, banana gate, direct gate, tab gate, hot runner valve gate, hot runner to cold runner, etc. |

Lead time 1st Trial | 20-45Days based on different molds |

Outside package | Standard wooden cases or as your requirement |

Inner package | Stretch waterproof film & Each Mold painted, anti-rust oil.3. Spare parts together with the mold shipment. 4. Vaccum package |

CUSTOM SOLUTION

MANUFACTURING TECHNIQUEABOUT USCERTIFICATESHIPPING & PAYMENTFAQ| Q1: What is your company's main product? |

| A: Our company is specialized in injection molding moulds and injection plastic products. We can customize all kinds of injection plastic products according to your requirements or 3D drawing. |

| Q2: How can I get the samples to check the quality? |

| A: 1) You can come to have the mould test directly. 2) We could send samples & mould running video to you. |

| Q3: Can you make multi-cavity molds? |

| A: Yes, we are capable of making molds in 16, 24, 48, and 64 cavities. |

| Q4: What certificates are you qualified for? |

| A: We are qualified in ISO9001, and we have a system for TS16949. |

| Q5: How do you make our business a long-term and good relationship? |

| A:1. We keep good quality, on-time delivery, and competitive price to ensure our customers benefit from the best quality products 2. We value each customer, no matter where they come from, or how big the order they place. |

| Q6: I have an idea for a new product, but don't know if it can be manufactured. Can you help? |

| A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials tooling and likely set-up costs. |

aNUmmFACTURING TECHN

PRODUCT PARAMEERS

PT PAAMENT