Hardware Mold for Die Casting Spare Parts

Basic Info

| Model NO. | D0227 |

| Machining | CNC Machining |

| Material | Aluminum |

| Surface Preparation | Deburring |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 3 |

| Certification | ISO 9001:2000 |

| OEM | Yes |

| Factory | Yes |

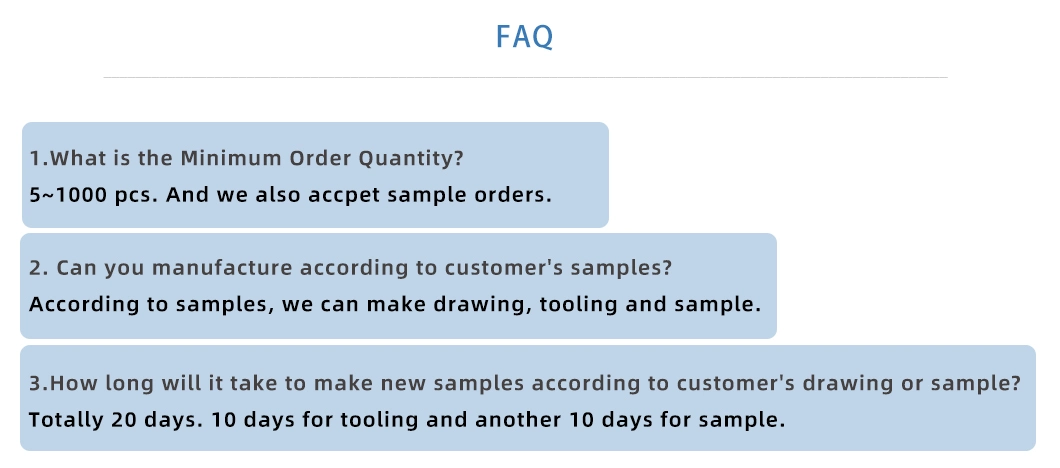

| MOQ | 1000 |

| Customizable Trademark | Yes |

| Transport Package | Safety Export Package |

| Specification | CE, SGS |

| Origin | Zhejiang, Lishui |

| Production Capacity | 1000000pieces/Year |

Packaging & Delivery

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 20.000kgProduct Description

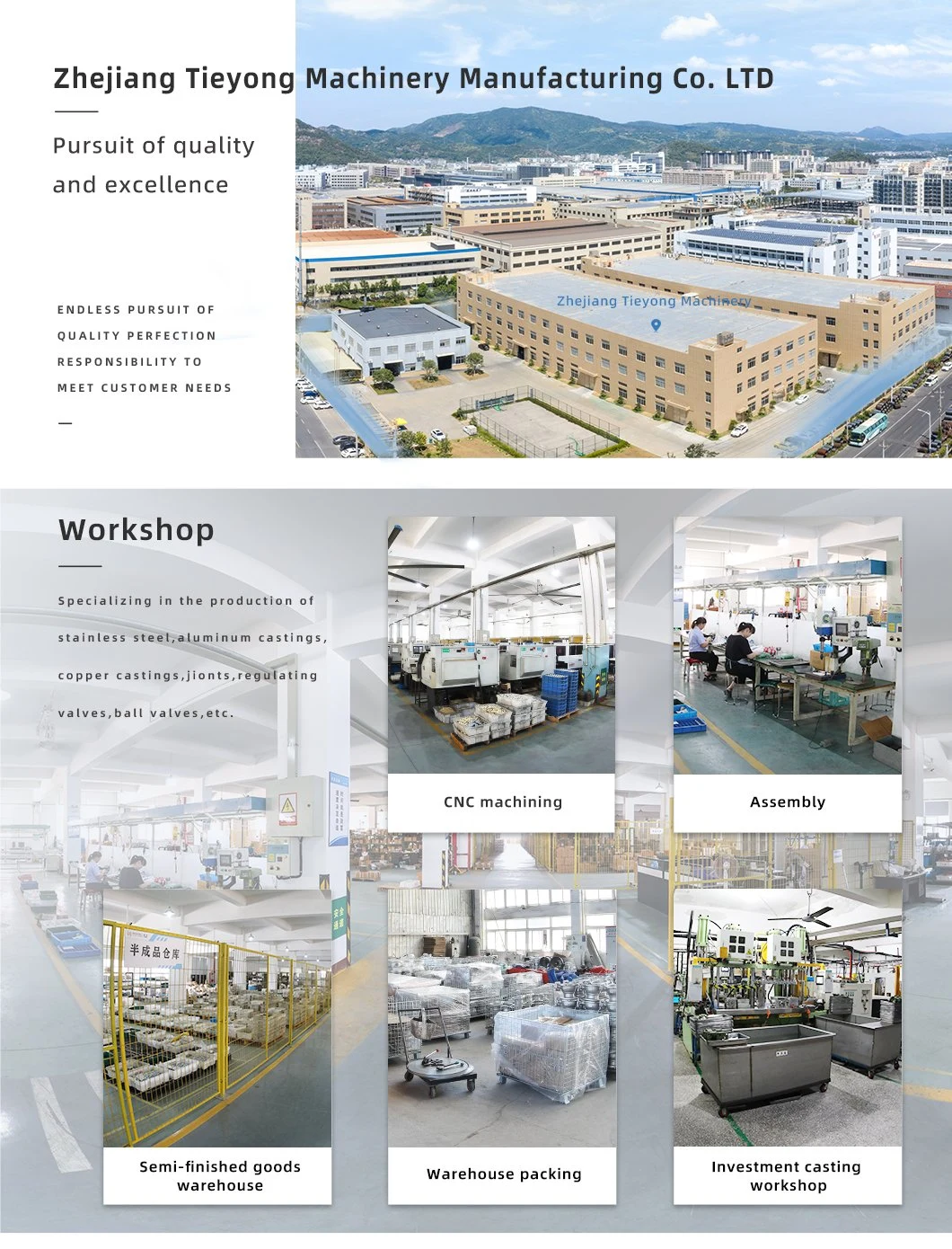

Zhejiang Tieyong Machinery Manufacturing is located in Gaohu Industrial Zone, Gaohu Town, Qingtian County, Zhejiang Province, China. Foundry company covers an area of 17,000 square meters, building area of 13,000 square meters; Copper Aluminum Zinc Company covers an area of 20000 square meters. We are good at making all kinds of mechanical parts. Our production processes include investment casting (precision casting), coated sand casting, lost mold casting, calcination, red stamping, machining (CNC machining), rod machining, injection molding and stamping. We have 8 wax shooting machines with 13 stations, 2 sets of shell drying line, 1 set of disappearing mold production line, 1 set of coated sand production line, 1 set of forging line, 6 sets of medium frequency casting furnace, more than 30 sets of solid solution after cleaning, investment casting spectral analysis instruments. More than 30 sets of die-casting red forging, 16 sets of injection molding machines, 3 sets of high material high-speed extrusion production lines, 10 sets of punching press, more than 200 sets of finishing equipment. Material range includes stainless steel, carbon steel, alloy steel, copper alloy, aluminum alloy, zinc alloy, plastic and so on. There are 10 technical engineers, 4 inspection engineers, 2 production engineers, 42 technical production masters of each specialty, and more than 400 other operating personnel. Our company is export-oriented, selling to Australia, USA, Canada, UK, (UK, UK), Netherlands, France, Germany, Denmark, Sweden, Finland, Russia, Spain, Portugal. The products are widely used in heavy equipment, automotive spare parts, Marine parts, petrochemical processing, wind turbine equipment, power plant, substation accessories, food processing industry and medical instruments. We do non-standard customized mechanical parts, can be produced according to the demand. "Integrity-based, quality first, service first" is our business philosophy, unity and enterprising, better, faster, stronger is our most sought goal, we are committed to build a talent team, integrate industry resources, and strive to further develop into a great machine parts manufacturing enterprise. We look forward to working with you to create a better future.

| Casting Machine | Die casting machine 88 ton, 125 ton, 200 ton, 280 ton, 400ton, 500 ton, 800 ton,1000 ton |

| Material | Aluminum alloy ADC10 ADC12 ADC14 A360 A380, zinc alloy |

| Casting Mold | Design, Fabrication, Test, Modification & Maintenance |

| Surface Treatment | Sandblasting, Polishing, Plating, Powder Coating, Anodisation etc |

| Accuracy | Class CT4~CT11 |

| Surface Roughness | Ra1.6~Ra6.3 |

| Machining Equipment | 3/4/5 Axis CNC machining center, CNC engraving machine, CNC milling machine |

| CNC turning machine, high precision grinding machine, WEDM etc |