Category

Plastic Mold Manufacturer OEM Auto Spare Parts Plastic Car Helmet Lamp Shell Plastic Injection Mould

Overview Package size per unit product 10.00cm * 5.00cm * 1.00cm Gross weight per unit product 0.500kg Plastic Mold Manu

Basic Info

| Model NO. | HKM2102197 |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Injection Mold |

| Application | Car, Auto Parts |

| Runner | Cold Runner |

| Design Software | 2D & 3D |

| Installation | Fixed |

| Certification | ISO, SGS |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 2years |

| Mould | Plastic Mould |

| Plastic | Plastic Product |

| Mold | Plastic Mold |

| Tooling | Toolings |

| Plastic Injection Mold | Injection Mold |

| Plastic Products | Plastic Parts |

| Transport Package | Wood Case |

| Specification | Customize |

| Trademark | HKM |

| Origin | Guangdong Dongguan |

| Production Capacity | 500 Sets of Moulds Per Year |

Packaging & Delivery

Package size per unit product 10.00cm * 5.00cm * 1.00cm Gross weight per unit product 0.500kgProduct Description

Plastic Mold Manufacturer OEM Auto Spare Parts Plastic Car Helmet Lamp Shell Plastic Injection Mould.Product Description| Product Name | Plastic Mold Manufacturer OEM Auto Spare Parts Plastic Car Helmet Lamp Shell Plastic Injection Mould |

| Material | ABS,PP,PC,PEEK,PEI,TPE,ABS+TPE or any other material as you need |

| Type of enterprise | Professional manufacturer of injection molds and plastic parts |

| Service | Design based on your idea or Make mold and produce based on your drawing |

| Design software | 3D&2D |

| Drawing format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

| Size | As Customer's Requst |

| Product weight | 100kg-20000kg |

| Production ability | Export about 400 to 500 sets of moulds per year. |

| Lead time | 1-5 weeks |

| Assembly & Test | Professional assembly and testing factory |

| Package | Wood case, standard carton, pallet or customized |

| Payment details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc |

| Shipping way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air |

| Features & Advantage | 1.Professional design team |

| 2.Professional moldflow analysis | |

| 3.Professional mold making team | |

| 4.Professional mold and product QC and technical team | |

| 5.Rich mould making experience for different country clients | |

| Standard | ISO9001:2015, SGS |

| Application | Auto Parts,Airplane Parts,Household Parts,BMC mold,Appliance Mold,Powertool,Communication parts,Overmold,Insertmold,Unscrewing Mold,Caps,Pipe fitting parts,PVC parts,Micro Precision Mold,High Performance Material mold,Infrared Thermometer,Other Molds. |

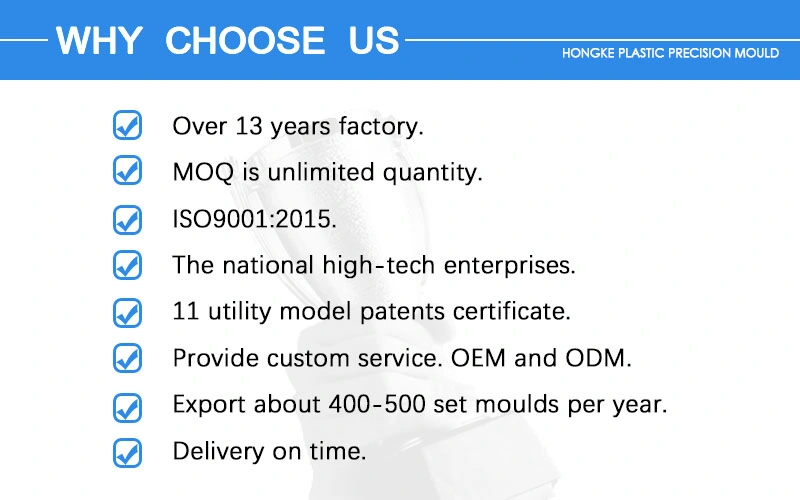

Hongke Plastic Precision Mould Co., Limited was established in 2008,as an excellent Chinese manufacturer specializes in mould making and injection molding. We are involved in the field of aero seats, auto parts, household appliances, power tools, medical equipment and etc. We have a strong team of skilled and experienced mould design engineers, NC design engineers, and mould making masters. We are good at complicated mould, precision mould, and large mould making. And we also have rich experience in over mould, double injection mould, unscrewing mould, and high performance material mould.We obtained ISO 9001:2015quality system certificate. We have tens of processing and testing equipment including high speed CNC machine, mirror EDM, precision grinder, lathe, milling machine, drilling machine, tapping machine, injection molding machine and three coordinate measuring machine.

Our factory building area of 5000 square meters, More than 80 employees, Export about 400 to 500 sets of moulds per year.